Ishidi le-G11-H Epoxy Fiberglass Laminated

Umyalelo Womkhiqizo

Izinto ze-G11-H ziyindlela yokwelapha yamakhemikhali kagesi enenhloso ye-alkali-free fiberglass reinforced laminates, ehlanganiswe ne-TG epoxy resin ephezulu. Inamandla omshini aphezulu ngaphansi kwezinga lokushisa elijwayelekile, isenamandla aqinile emishini, izakhiwo ezinhle zikagesi ngaphansi kwemvelo eyomile nemanzi, ingasetshenziswa endaweni emanzi kanye nowoyela we-transformer.

Ukuhambisana nezindinganiso

Ngokuvumelana ne-GB/T 1303.4-2009 kagesi thermosetting resin industrial hard laminates - Ingxenye 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating materials - electronic thermosetting resin industrial hard laminates - Ingxenye 3-2 ye-EPGC3 yokucaciswa kwempahla ngayinye.

Isicelo

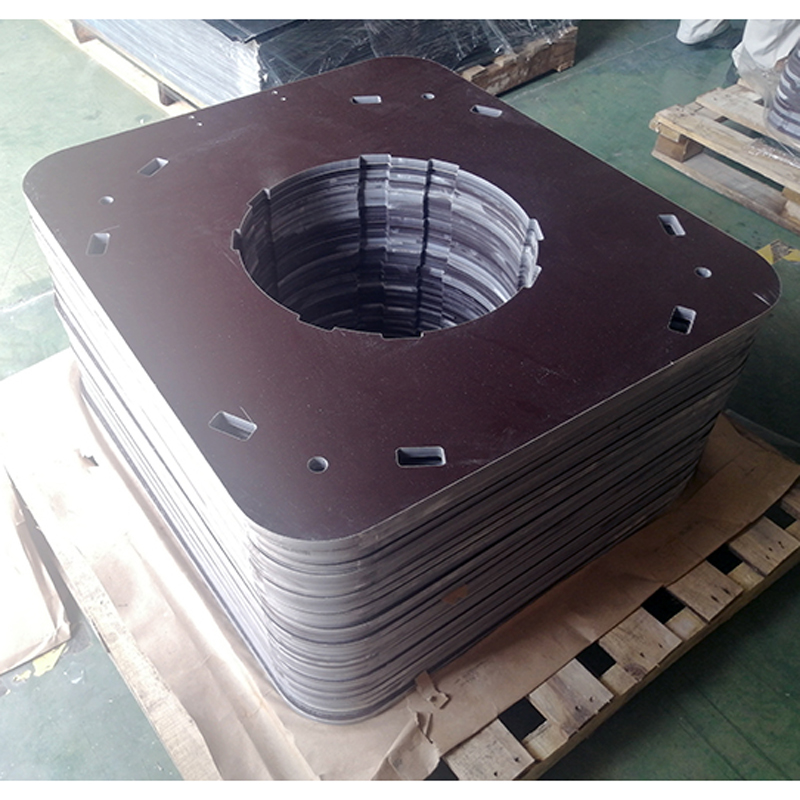

Ifanele ama-traction motors ekilasi le-180 (H), amamotho amakhulu njengama-slot wedge kanye nezinto zikagesi ezisezingeni eliphezulu njengemiphumela yokuvikela ukumelana nokushisa,

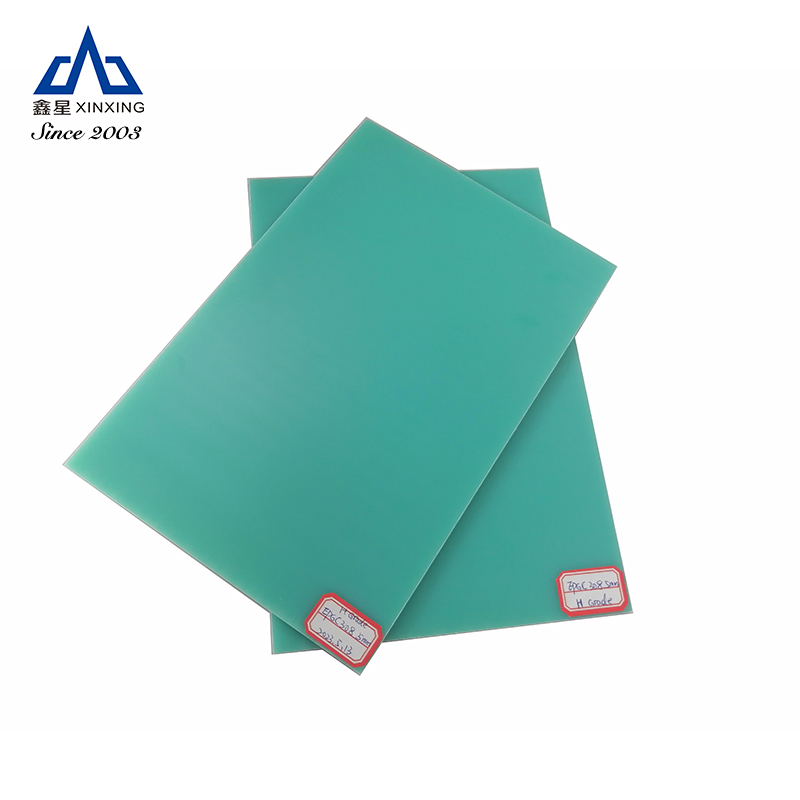

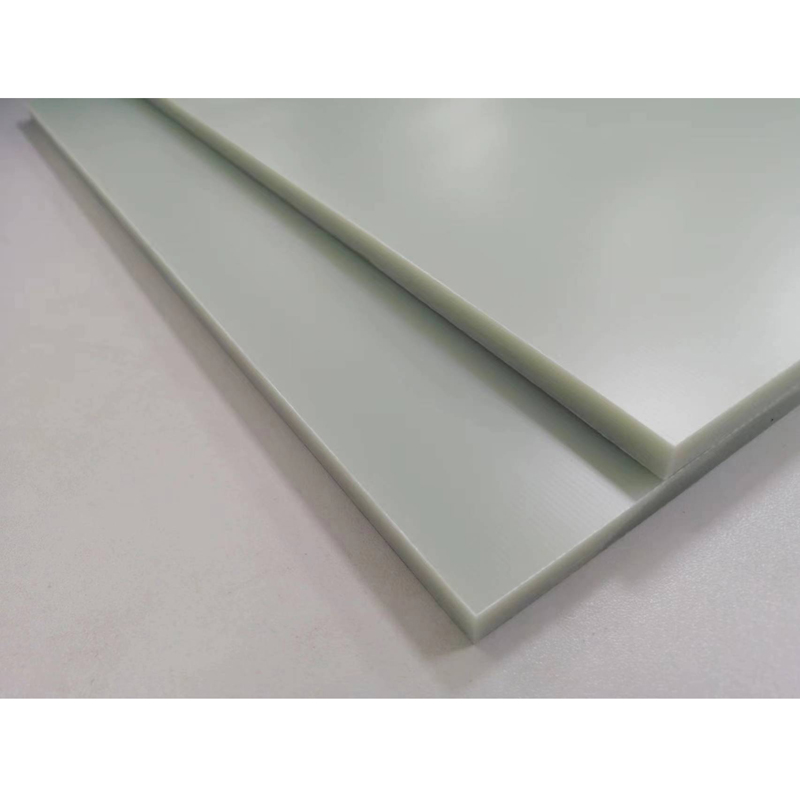

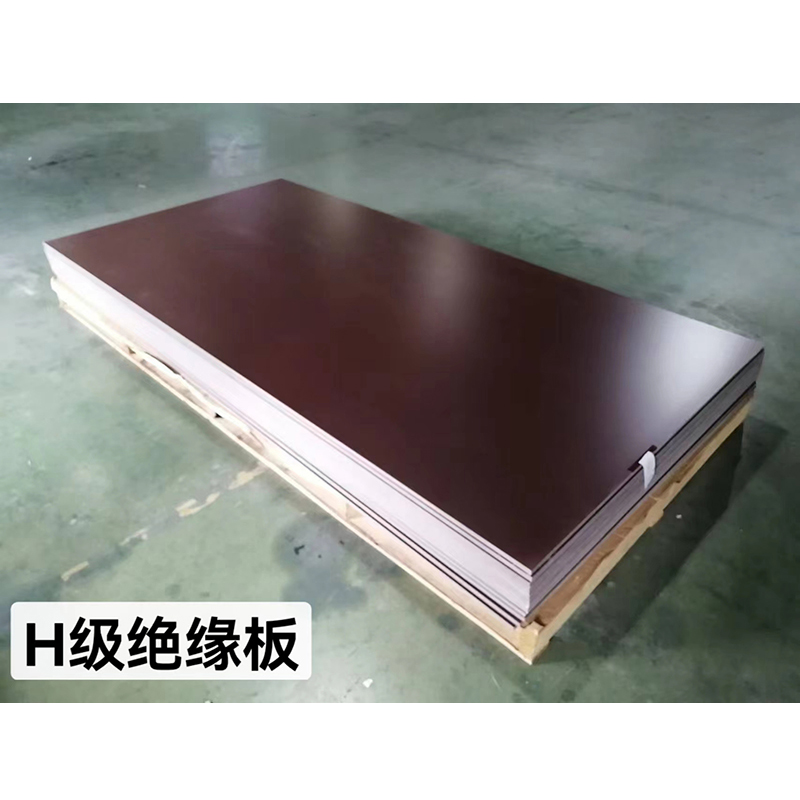

Izithombe zomkhiqizo

Idethi Eyinhloko Yobuchwepheshe(Chofoza lapha ukuze ulande umbiko wokuhlola wenkampani yangaphandle)

| Into | Impahla | Iyunithi | Inani Elijwayelekile | Inani Elijwayelekile | Indlela Yokuhlola |

| 1 | Amandla e-Flexural perpendicular to laminations(MD,23℃±2℃) | I-MPa | ≥380 | 556 | I-GB/T 1303.2 |

| 2 | Amandla e-Flexural perpendicular to laminations(MD,180℃±2℃) | I-MPa | ≥190 | 298 | |

| 3 | Amandla e-Flexural perpendicular to laminations(MD,23℃±2℃) | I-MPa | _ | 24252 | |

| 4 | Amandla womthelela we-Charpy ahambisana nama-laminations (Notched, MD) | kJ/m2 | ≥37 | 111 | |

| 5 | Amandla e-Tensile(MD) | I-MPa | ≥300 | 557 | |

| 6 | Amandla acindezelayo ahambisana nama-laminations(23℃±2℃) | I-MPa | ≥380 | 640 | |

| 7 | Amandla acindezelayo ahambisana nama-laminations(180℃±2℃) | I-MPa | ≥190 | 378 | |

| 8 | Amandla kagesi ahambisana nama-laminations (ku-90℃±2℃ ku-25# uwoyela we-transformer, ukuhlolwa kwesinyathelo nesinyathelo se-20s, Φ25mm/Φ75mm i-cylindrical electrode) | kV/mm | ≥14.2 | 19.2 | |

| 9 | Ukwehla kwamandla kagesi ahambisana nama-laminations (ku-90℃±2℃ ku-25# uwoyela we-transformer, ukuhlolwa kwesinyathelo nesinyathelo se-20s, Φ130mm/Φ130mm plate electrode) | kV | ≥45 | >100 | |

| 10 | Imvume Ehlobene(1MHz) | _ | ≤5.5 | 5.20 | |

| 11 | I-Dielectric dissipation factor(1MHz) | _ | ≤0.04 | 0.0102 | |

| 12 | Ukumelana nokufakwa kwe-insulation ngemva kokucwiliswa emanzini (MD, i-taper pin electrode, igebe elingu-25.0mm) | Ω | ≥5.0 x1010 | 2.6x1014 | |

| 13 | Ukumuncwa kwamanzi | mg | ≤22 | 18.00 |

|

| 14 | Ukuminyana | g/cm3 | 1.7-2.0 | 1.98 | |

| 15 | Inkomba yezinga lokushisa | ℃ | _ | 180 ℃ | |

| 16 | TG | ℃ | _ | 200℃±5℃ |

FAQ

Q1: Ingabe uhweba inkampani noma umenzi?

Singumkhiqizi oholayo wenhlanganisela kagesi efaka insulating, besisebenza kumkhiqizi we-thermoset rigid composite kusukela ngo-2003.Umthamo wethu ngu-6000TONS/ngonyaka.

Q2: Amasampula

Amasampuli amahhala, udinga kuphela ukukhokhela izindleko zokuthumela.

Q3: Uliqinisekisa kanjani izinga lokukhiqiza ngobuningi?

Ngokubukeka, usayizi nokuqina: sizokwenza ukuhlola okugcwele ngaphambi kokupakisha.

Ngekhwalithi yokusebenza: Sisebenzisa ifomula engashintshi, futhi kuzoba ukuhlolwa kwamasampula okuvamile, singanikeza umbiko wokuhlola umkhiqizo ngaphambi kokuthunyelwa.

Q4: Isikhathi sokulethwa

Kuya ngenani le-oda.Ngokujwayelekile, isikhathi sokulethwa sizoba yizinsuku eziyi-15-20.

Q5: Iphakheji

Sizosebenzisa iphepha lobuciko obuchwepheshile ukupakisha ku-plywood pallet.uma unezidingo zephakheji ezikhethekile, sizopakisha njengesidingo sakho.

Q6: Inkokhelo

I-TT, 30% T/T kusengaphambili, ibhalansi ngaphambi kokuthunyelwa.Siphinde samukela i-L/C.