Ishidi le-3250 Epoxy Fiberglass Laminated(G11-H)

Umyalelo Womkhiqizo

Izinto ezingama-3250 ziyindlela yokwelapha yamakhemikhali kagesi ehloselwe i-fiberglass engena-alkali eqinisiwe, ehlanganiswe ne-TG epoxy resin ephezulu. Inamandla amakhulu okusebenza ngaphansi kwezinga lokushisa elijwayelekile, isenamandla aqinile emishini, izakhiwo ezinhle zikagesi ngaphansi kwemvelo eyomile nemanzi, ingasetshenziswa imvelo enomswakama kanye nowoyela we-transformer.Kungokwesigaba H sezinto zokuvikela ukushisa.

Ukuhambisana nezindinganiso

I-TS EN 60893-3-2-2009 I-TS EN 60893-3-2-2011 izinto zokuvikela zikagesi ze-thermosetting resin - Ingxenye 4: I-epoxy resin hard laminates Imininingwane EPGC308.

Isicelo

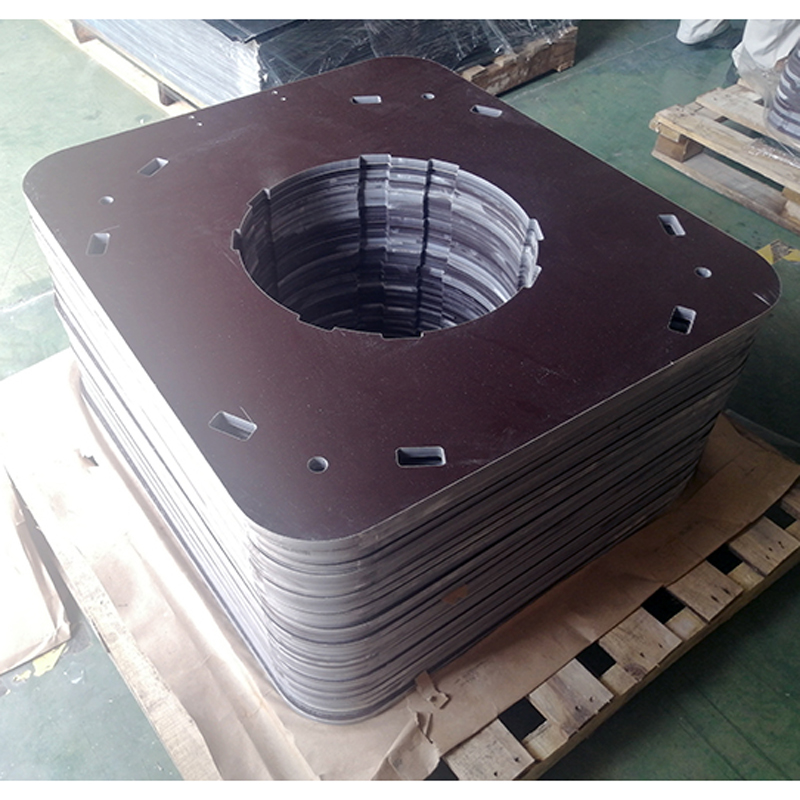

Ifanele ama-traction motors ekilasi 180 (H), amamotho amakhulu njengama-slot wedge kanye nezinto zikagesi ezisezingeni eliphezulu njengemiphumela yokungashisi ukushisa,

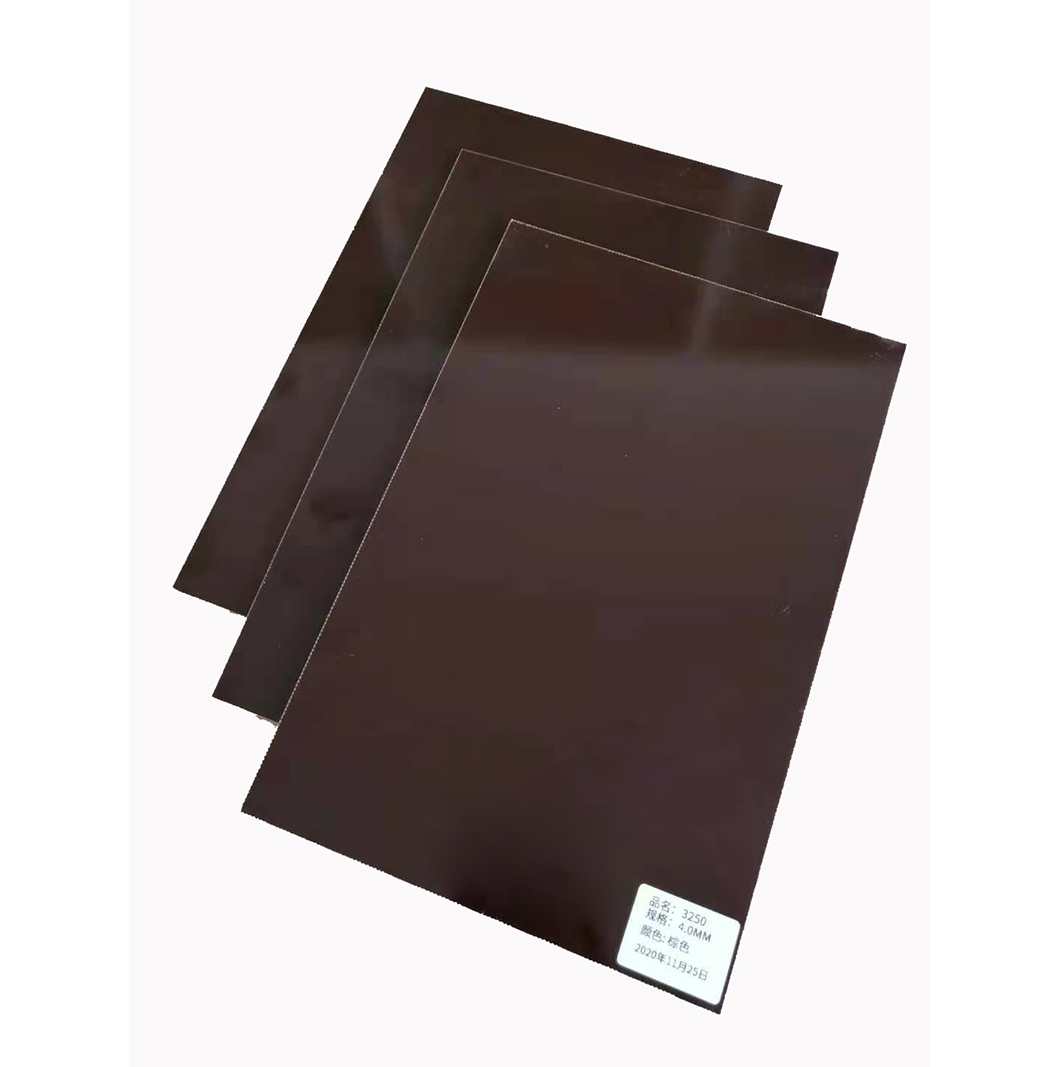

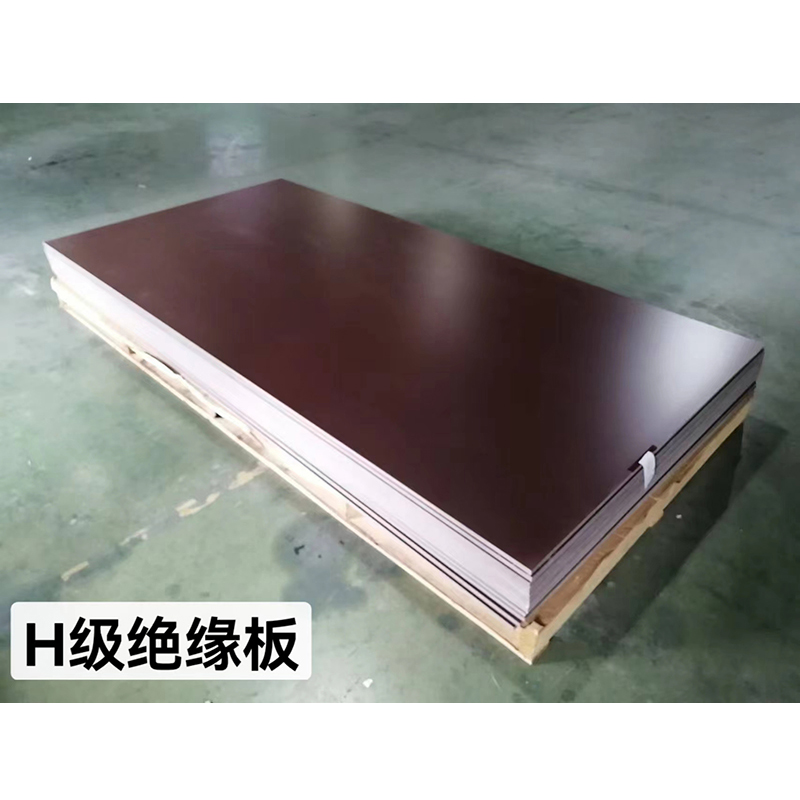

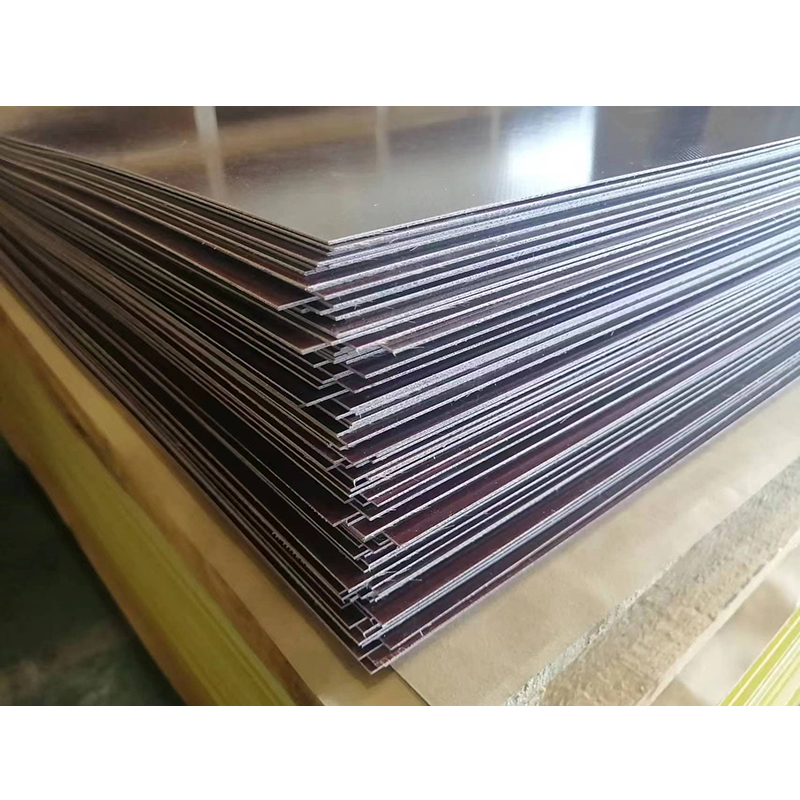

Izithombe zomkhiqizo

Idethi Eyinhloko Yobuchwepheshe(Chofoza lapha ukuze ulande umbiko wokuhlola wenkampani yangaphandle)

| Into | Impahla | Iyunithi | Inani Elijwayelekile | Inani Elijwayelekile | Indlela Yokuhlola |

| 1 | Amandla e-Flexural perpendicular to laminations(MD,23℃±2℃) | I-MPa | ≥380 | 644 | I-GB/T 1303.2 |

| 2 | Amandla e-Flexural perpendicular to laminations(MD,180℃±2℃) | I-MPa | ≥190 | 320 | |

| 3 | Amandla womthelela we-Charpy ahambisana nama-laminations (Notched, MD) | kJ/m2 | ≥37 | 114 | |

| 4 | Amandla e-Tensile(MD) | I-MPa | ≥300 | 402 | |

| 5 | Amandla acindezelayo ahambisana nama-laminations(23℃±2℃) | I-MPa | ≥380 | 640 | |

| 6 | Amandla acindezelayo ahambisana nama-laminations(180℃±2℃) | I-MPa | ≥190 | 378 | |

| 7 | Amandla kagesi ahambisana nama-laminations (ku-90℃±2℃ ku-25# uwoyela we-transformer, ukuhlolwa kwesinyathelo nesinyathelo se-20s, Φ25mm/Φ75mm i-cylindrical electrode) | kV/mm | ≥14.2 | 19.3 | |

| 8 | Ukwehla kwamandla kagesi ahambisana nama-laminations (ku-90℃±2℃ ku-25# uwoyela we-transformer, ukuhlolwa kwesinyathelo nesinyathelo se-20s, Φ130mm/Φ130mm plate electrode) | kV | ≥45 | >100 | |

| 9 | Imvume Ehlobene(1MHz) | _ | ≤5.5 | 5.20 | |

| 10 | I-Dielectric dissipation factor(1MHz) | _ | ≤0.04 | 0.019 | |

| 11 | Ukumelana ne-insulation ngemva kokucwiliswa emanzini (MD, taper pin electrode, 25.0mm gap) | Ω | ≥5.0 x1010 | 4.9x1014 | |

| 12 | Ukumuncwa kwamanzi | mg | ≤22 | 18.00 | |

| 13 | Ukuminyana | g/cm3 | 1.7-2.0 | 1.93 | |

| 14 | Inkomba yezinga lokushisa | ℃ | _ | 180 ℃ | |

| 15 | TG | ℃ | _ | 200℃±5℃ |

FAQ

Q1: Ingabe uhweba inkampani noma umenzi?

Singumkhiqizi oholayo wenhlanganisela kagesi efaka insulating, besisebenza kumkhiqizi we-thermoset rigid composite kusukela ngo-2003.Umthamo wethu ngu-6000TONS/ngonyaka.

Q2: Amasampula

Amasampuli amahhala, udinga kuphela ukukhokhela izindleko zokuthumela.

Q3: Uliqinisekisa kanjani izinga lokukhiqiza ngobuningi?

Ngokubukeka, usayizi nokuqina: sizokwenza ukuhlola okugcwele ngaphambi kokupakisha.

Ngekhwalithi yokusebenza: Sisebenzisa ifomula engashintshi, futhi kuzoba ukuhlolwa kwamasampula okuvamile, singanikeza umbiko wokuhlola umkhiqizo ngaphambi kokuthunyelwa.

Q4: Isikhathi sokulethwa

Kuya ngenani le-oda.Ngokujwayelekile, isikhathi sokulethwa sizoba yizinsuku eziyi-15-20.

Q5: Iphakheji

Sizosebenzisa iphepha lobuciko obuchwepheshile ukupakisha ku-plywood pallet.uma unezidingo zephakheji ezikhethekile, sizopakisha njengesidingo sakho.

Q6: Inkokhelo

I-TT, 30% T/T kusengaphambili, ibhalansi ngaphambi kokuthunyelwa.Siphinde samukela i-L/C.